Today I had the chance to learn to use a scanning electron microscope, courtesy of the Biology Department at Aberystwyth University. I was invited to bring along some materials for scanning (but was advised that biological matter would be a pain to prepare, so wouldn’t be ideal). So, I decided to bring along samples of different plastic filaments that I use for printing with my Lulzbot 3D printer. I spent some time being taught to use the machine, before my colleague and I were left to take our images.

Laywoo-D3

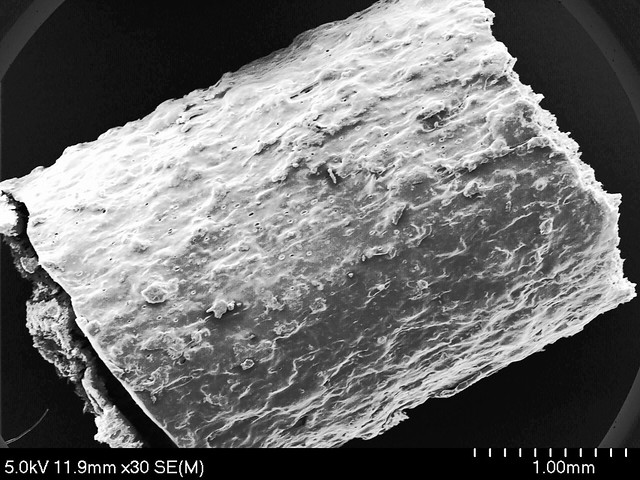

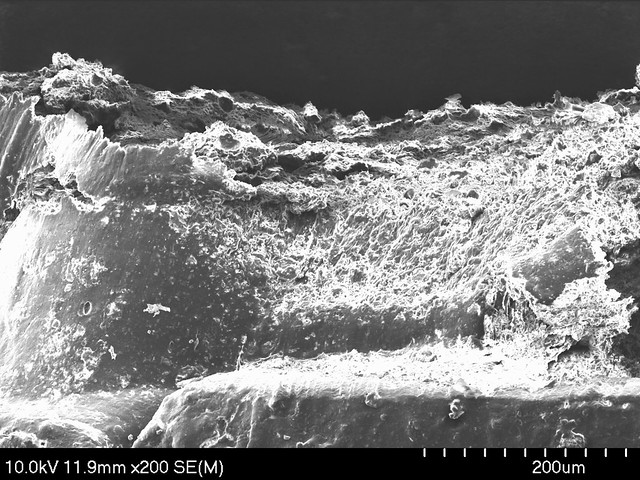

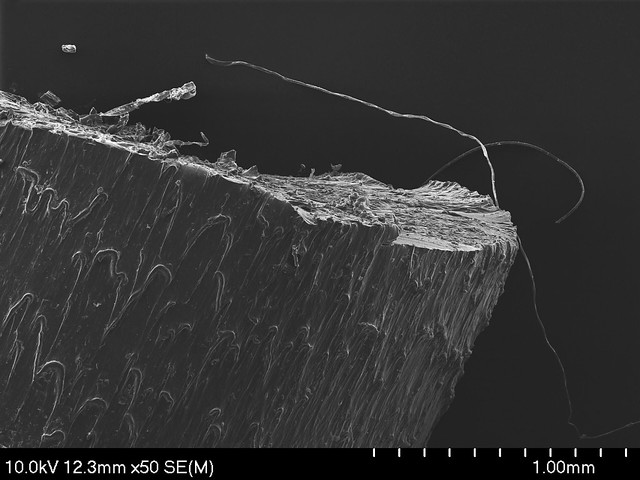

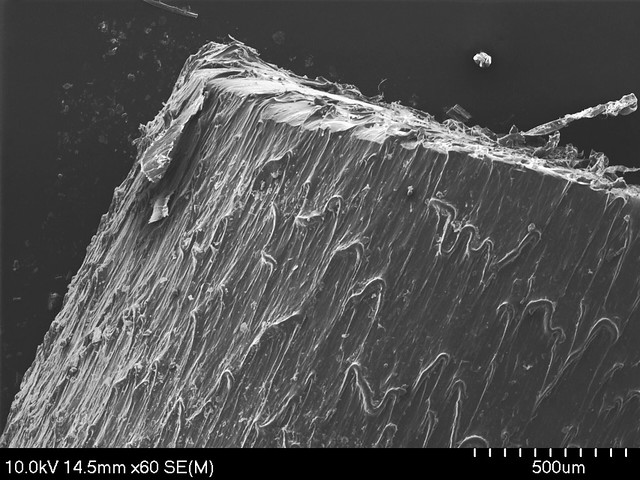

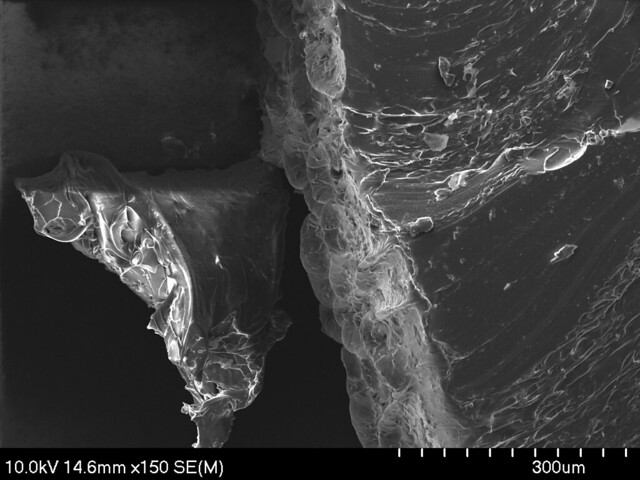

First up, we decided to take a look at the Laywoo-D3 filament. This filament is used to create a wood-effect in prints, and according to the Lulzbot website it is indeed “wood based”. Here are some of the pictures:

We did take more images than these, but it seems that we failed to save them correctly. The material looks quite different to how I expected. I envisioned small pieces of wood fiber embedded in a plastic, but I suppose that this could cause issues with blockages in an extruder.

Laybrick

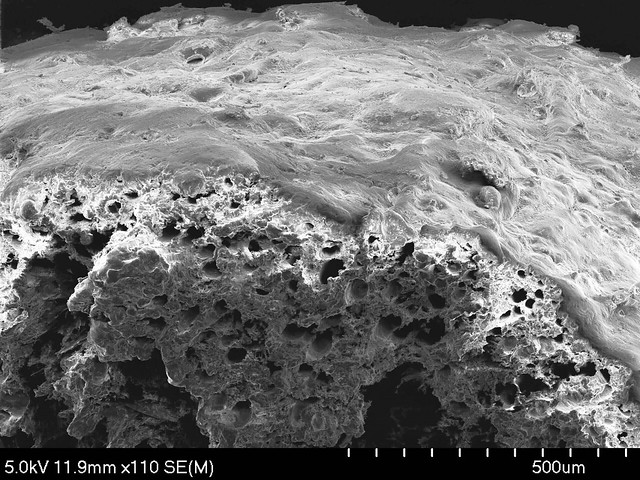

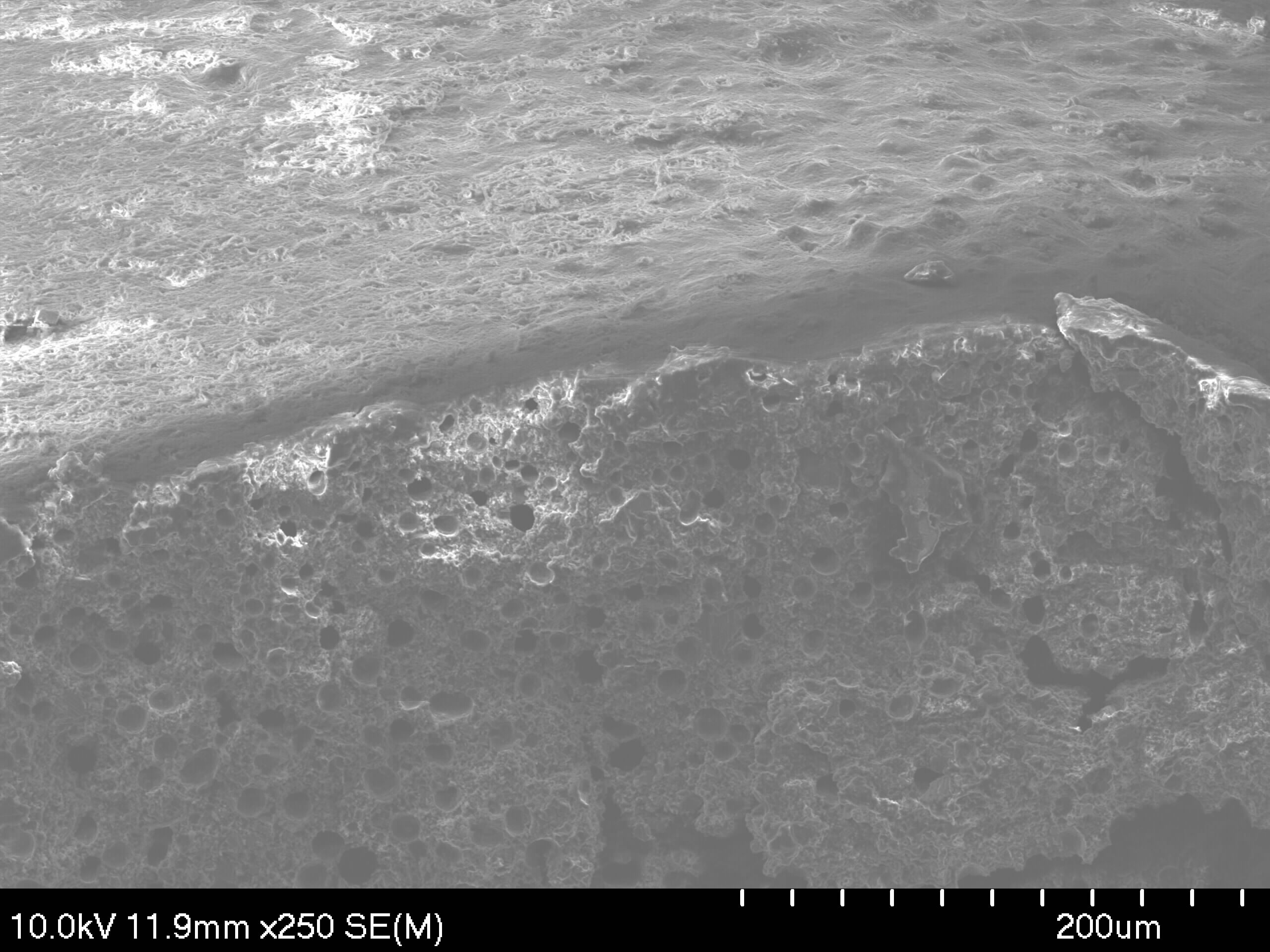

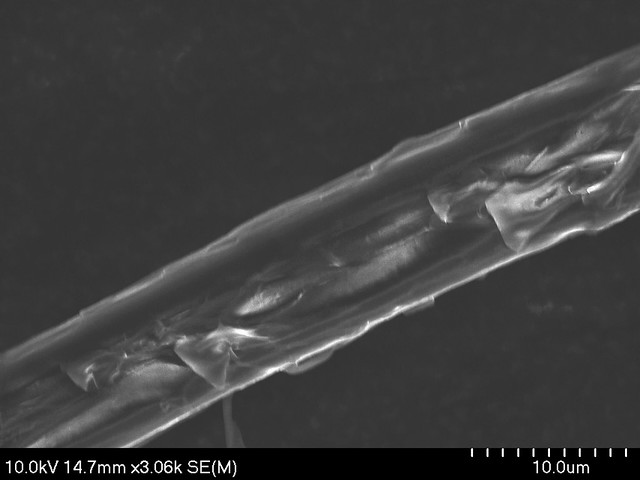

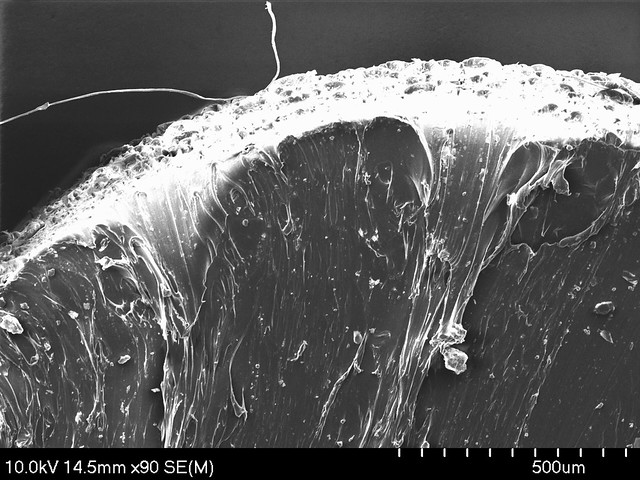

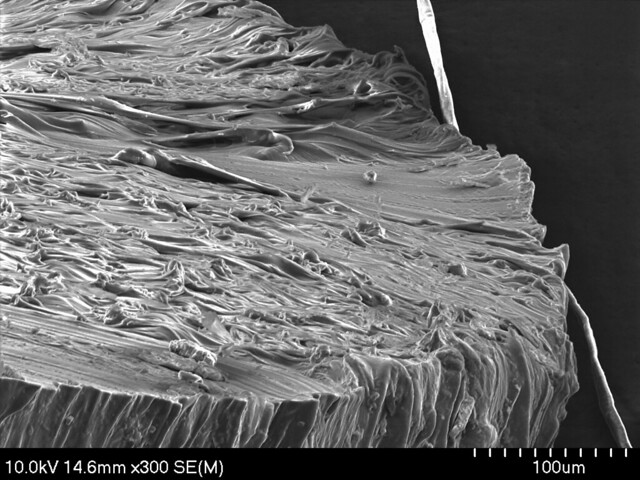

Next, we moved on to Laybrick. Laybrick is similar to Laywoo-D3, except that it contains mineral instead of wood fiber.

The Laybrick again looks different to how I had expected (I expected a more crystalline structure). It is infact quite similar looking to the Laywoo-D3 really. It is however a lot smoother and a lot more regular in it’s structure.

NinjaFlex

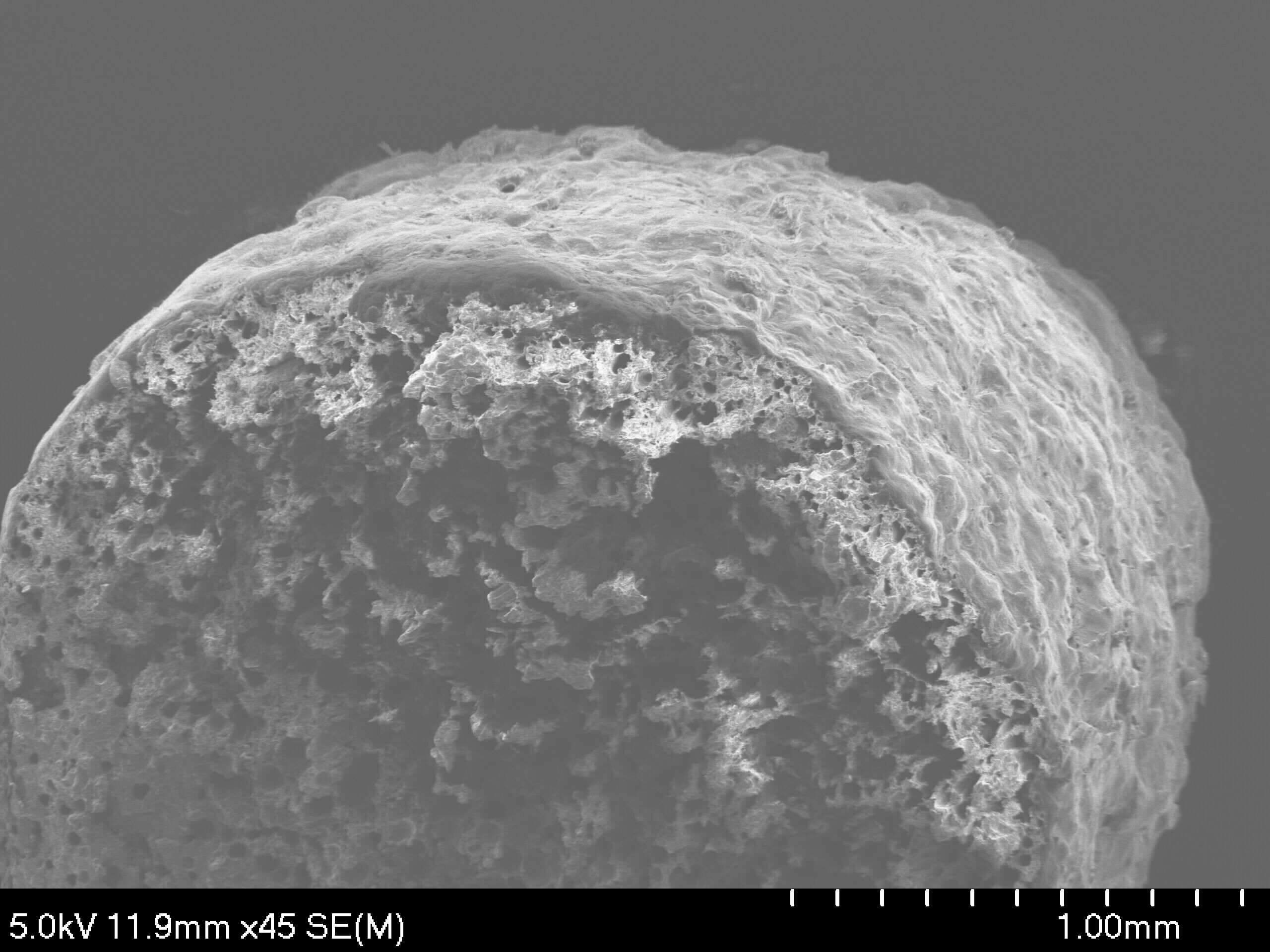

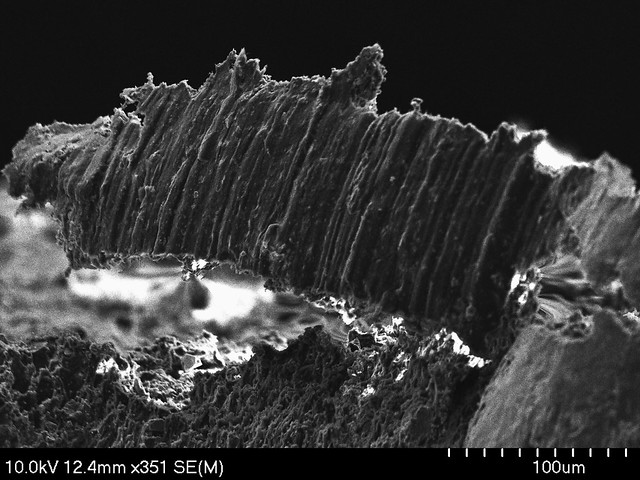

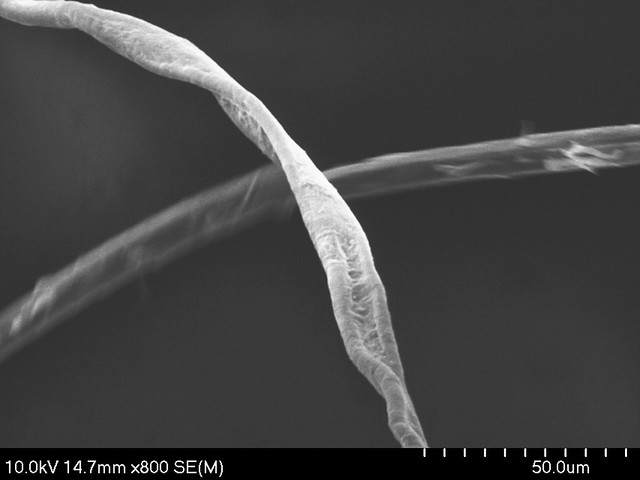

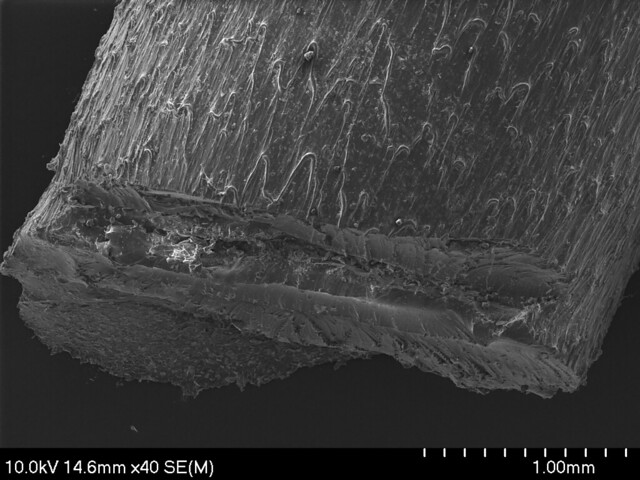

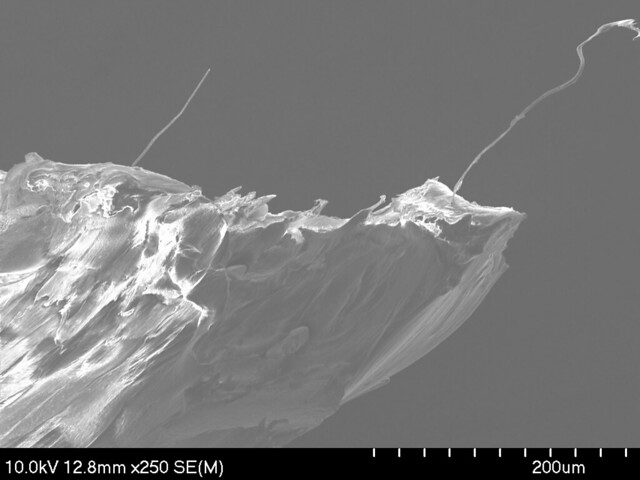

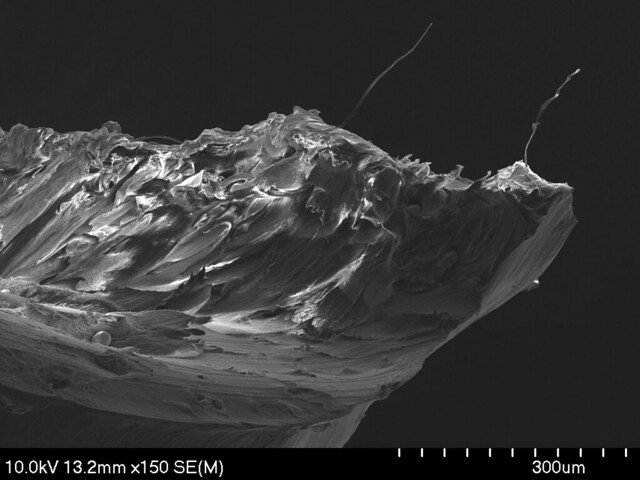

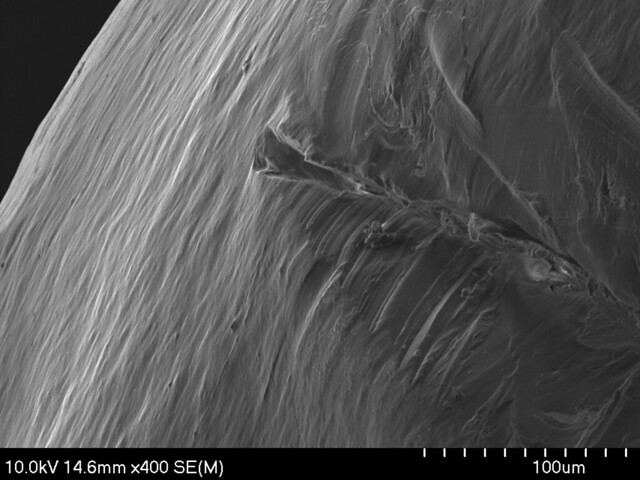

The next material to be investigated was NinjaFlex. This was my favorite material looked at.

Interestingly, in a lot of these images you can see where the material was “dragged” inwards when it was cut. A crevice can also be seen from a failed attempt at cutting. The NinjaFlex seems quite fiborous, with numerous small strands coming away from it. The inside however seems to be a fairly solid material, lacking the holes seen in the Laywoo-D3 and Laybrick.

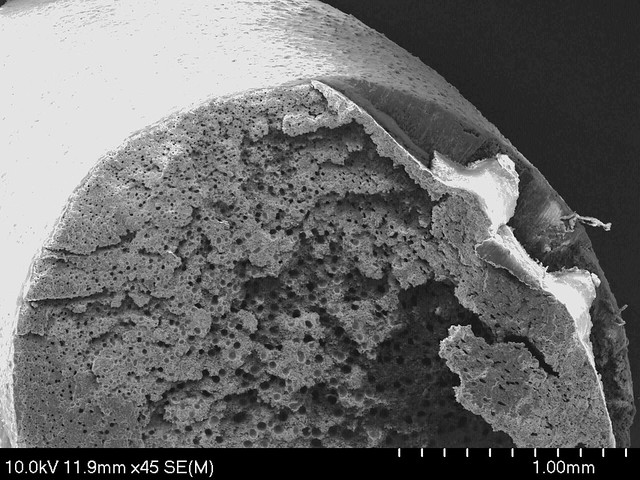

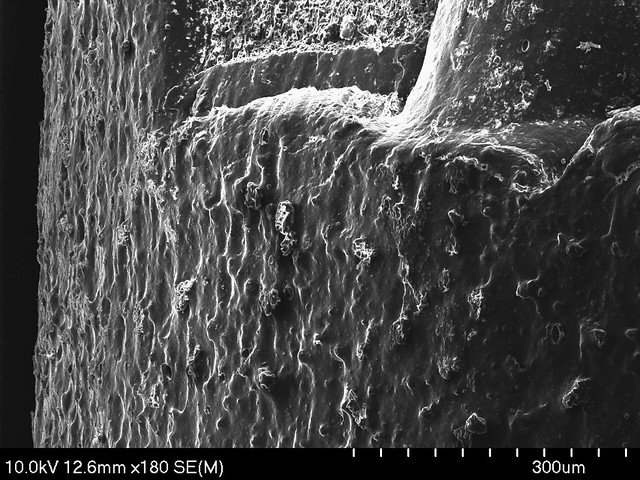

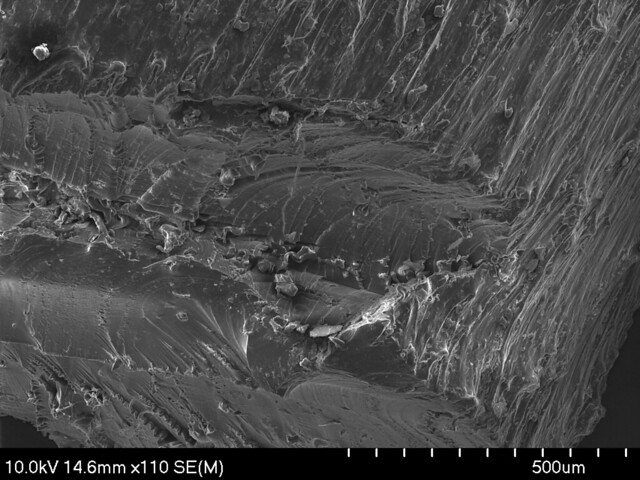

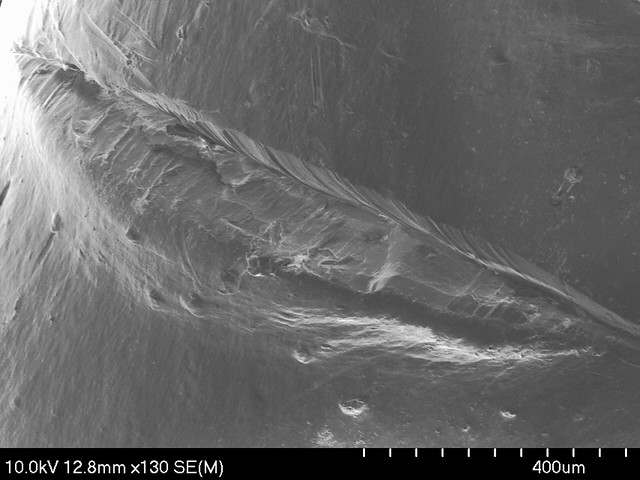

Glow in the Dark ABS

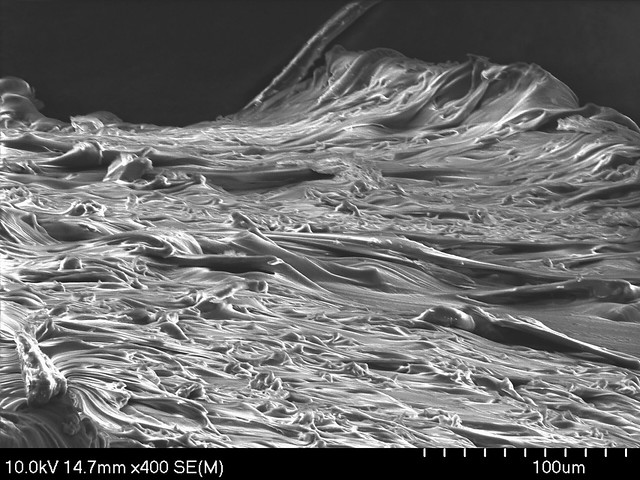

To act as a sort of baseline, we decided to look at some ABS filament. I decided to use the Glow in the Dark ABS filament I had, to see if this created any interesting effects. There were some issues with the SEM’s charge when we were attempting to take images of the ABS, which limited what we could get.

This material was fairly uninteresting. It had a smooth exterior and a solid interior. We were unfortunately unable to take any real “zoomed out” views of the material.

It was certainly an interesting trip, and I am hoping to be able to take more images in the future!

Be First to Comment